Current Location:Products:Valve Pair

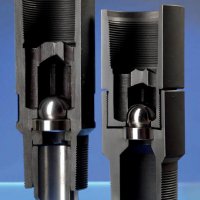

Finished TC ball and seat

The valve ball and seat is a important part of the oil field mining pump, its using directly decides the service life of pump.According to the corrosion characteristics of oil, oil Wells can provide different material

We can produce the API 11AX ball and seat in materials stainless steel AISI440C and hard alloy (tungsten carbide and STELLITE), with advantages of high hardness, wear resistance, corrosion resistance.

Each of our ball-and-seat combination is vacuum tested to ensure a perfect seal is obtained in all positions of contact.

Materials:

CODE | INSTRUCTION | HARDNESS | MATERIAL |

SS | Stainless steel | Ball: HRC 58-65 | 9Cr18Mo(AISI440C) |

ST | Cobalt alloy casting | Ball: HRC 56-63 | Cobalt, chromium and tungsten alloy |

ST | Cobalt alloy, powder metallurgy | Ball: HRC 53-60 | Cobalt, chromium and tungsten alloy |

TC | Tungsten carbide | Ball: HRA 88-89 | Tungsten with cobalt adhesive |

ZrO2 | Ceramic ZrO2 | HV 900-1300 | ZrO2 |

Size Table:

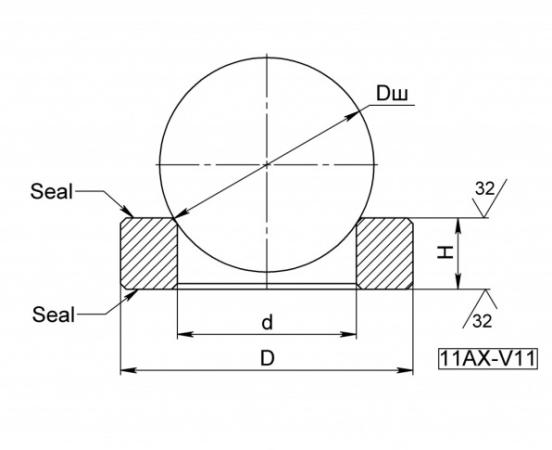

Type | Fluid, mm2 | Dш, mm | D, mm | d mm | H, mm |

V11-106 | 107 | 15.8750 | 20.142 | 11.68 | 12.70 |

V11-125 | 153 | 19.0500 | 23.317 | 13.97 | 12.70 |

V11-150 | 227 | 23.8125 | 29.667 | 17.02 | 12.70 |

V11-175 | 345 | 28.5750 | 35.255 | 20.96 | 12.70 |

V11-225 | 569 | 34.9250 | 43.688 | 26.92 | 12.70 |

V11-250 | 869 | 42.8625 | 51.054 | 33.27 | 12.70 |

V11-375 | 1623 | 57.1500 | 78.029 | 45.47 | 19,05 |

Application:

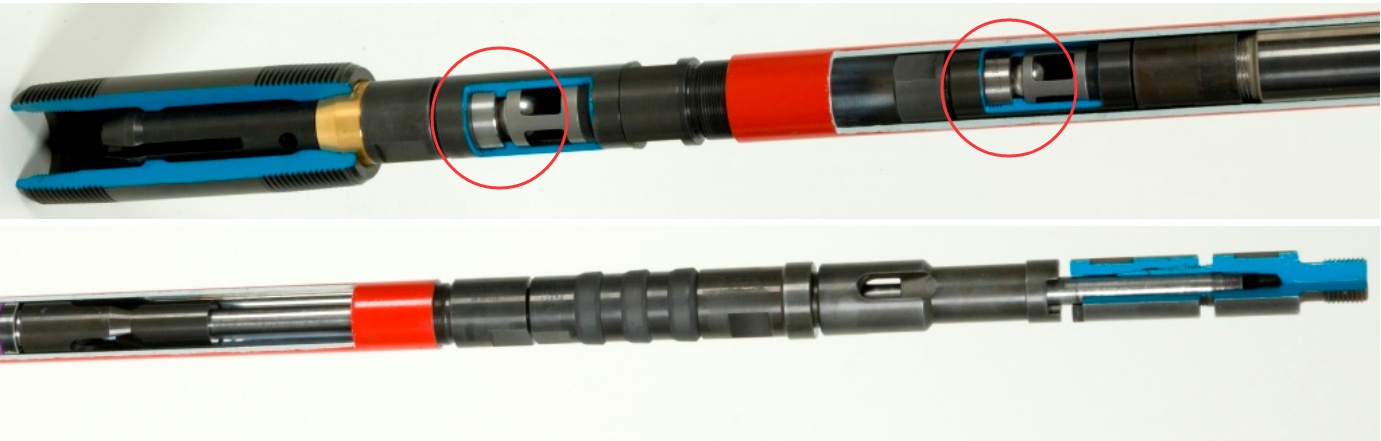

Valve balls and seats are used in the manufacture of valves of submersible sucker-rod pumps, a check valve used for oil and gas production. Valve balls and seats are the most critical parts of the pump, because it is subject to the greatest chemical and mechanical stress.

Packing:

PRODUCT CENTER

LEAVE A MESSAGE GET A QUOTATION Document download